Here I tried to see if it would work: Wizard of Wor on my 1541 Ultimate II+ stuck into my Magic Voice Module. Pick and fire up the game from my windows workstation over ftp or telnet or somethin’ I forget which.

Author: Industrial Power & Microelectronics, L.L.C. dba Milwaukee Mac Repair

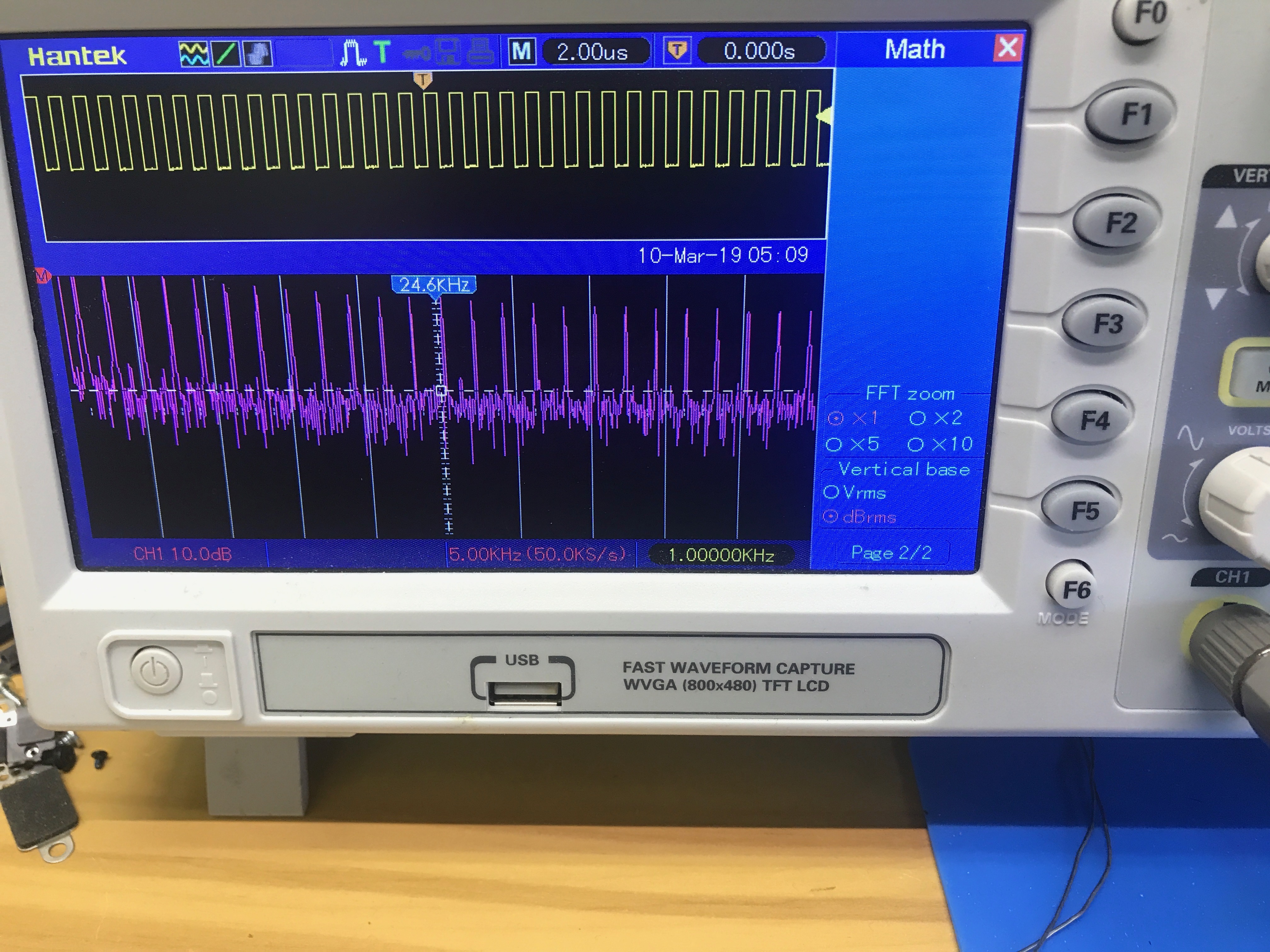

FFT mode near field

First test

For a “Near Field Probe” – it sure is picking up a ton of whatchahoozies.

Presently in my spare time I am building a poor-man’s Spectrum Analyzer / EMI near field probe setup. I have the Airspy and spyverter. I built a near field probe. I have a 30dB amp for the probe. I have 75-50Ω matcher. I have SDR# and Spectrumspy software. It’s all there. It just needs someone with a brain to make it all work. What WILL I do?!

Hard to find C64 title?

1541 Ultimate II+ works with Commodore magic voice. I had to telnet into 1541 ultimate II+ to fire up the GORF and WIZARD OF WOR crt images. Easy Flash works its magic.

Mail-in Board-level Repair

Laptop board repair

We fix more than Macbooks! Asus, Acer, HP, Dell, Lenovo – we bring these back to life every day. And cheap, too! Normally, it’s just a simple short on a power rail, a failed FET, a bad capactitor and/or liquid damage. Same stuff.

Most recent repairs include;

- A Dell and an Asus needed sneaky naughty capacitor replaced. Maybe a new FET. Parts we have in stock. Cheap parts, just a matter of diagnostics.

Out the door, running again for $140 with 90 day warranty.

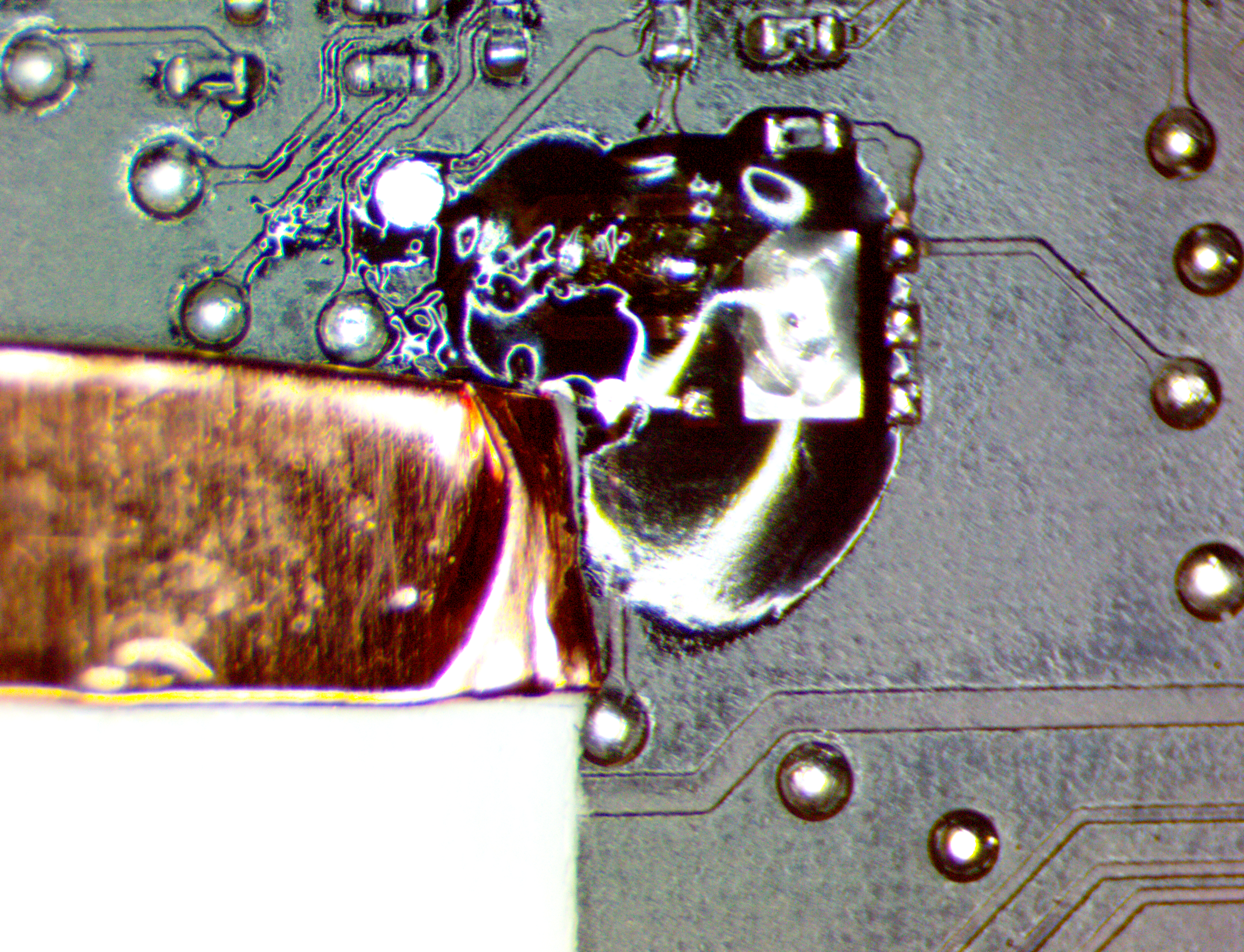

- A Toshiba with a charred shorted area where DC Power-In jack solders to the board.

It was obvious what the problem was. The remedy was an entirely different issue; It shorted for a reason! Diagnosis found manufacturing defect that lead to eventual short of copper layers inside board substrate. Thermal image verified charred region as suspect area. My dremel tool was used to grind away that area until + and – read a much higher resistance. Into the kOhms…that looks good. I conformal coated and corona doped the ground away area to protect them from future damage and to KEEP them separated (gotta keep ’em separated), rebuilt power and ground planes up, soldered new port on; it works. NEXT!

$140 – 90 day warranty

- A common laptop issue; The center pin on the DC-in power jack cracked! I see this alot. Why does it crack? At the strangest place, too. Stress, strain. The DC-in jack build is flimsy. I soldered some of my desoldering braid across this crack. this will allow some movement and not crack ever again without transferring undue new strain forces onto the circuit board through-hole pad. This was a remedy that shows an appreciation of what happened. A real fix that addresses and solves the problem instead of just putting a band-aid onto the effects of the problem. Better than a mindless replacement of the DC-in jack with the same OEM time-bomb trap built-in. THAT’S a service.

I charged the customer $70 and gave 90 day warranty.

Game console repair

XBOX one liquid damage – $70 fix or no pay

PS4 HDMI port replacement – $70 fix or no pay

Totally mod and rebuild an import PC Engine Duo RX inc. cdrom, caps, RGB, etc; You pay for parts, I do work for $150. Even rehab those old controllers so button press is perfect like new every time again.

Macbook repair

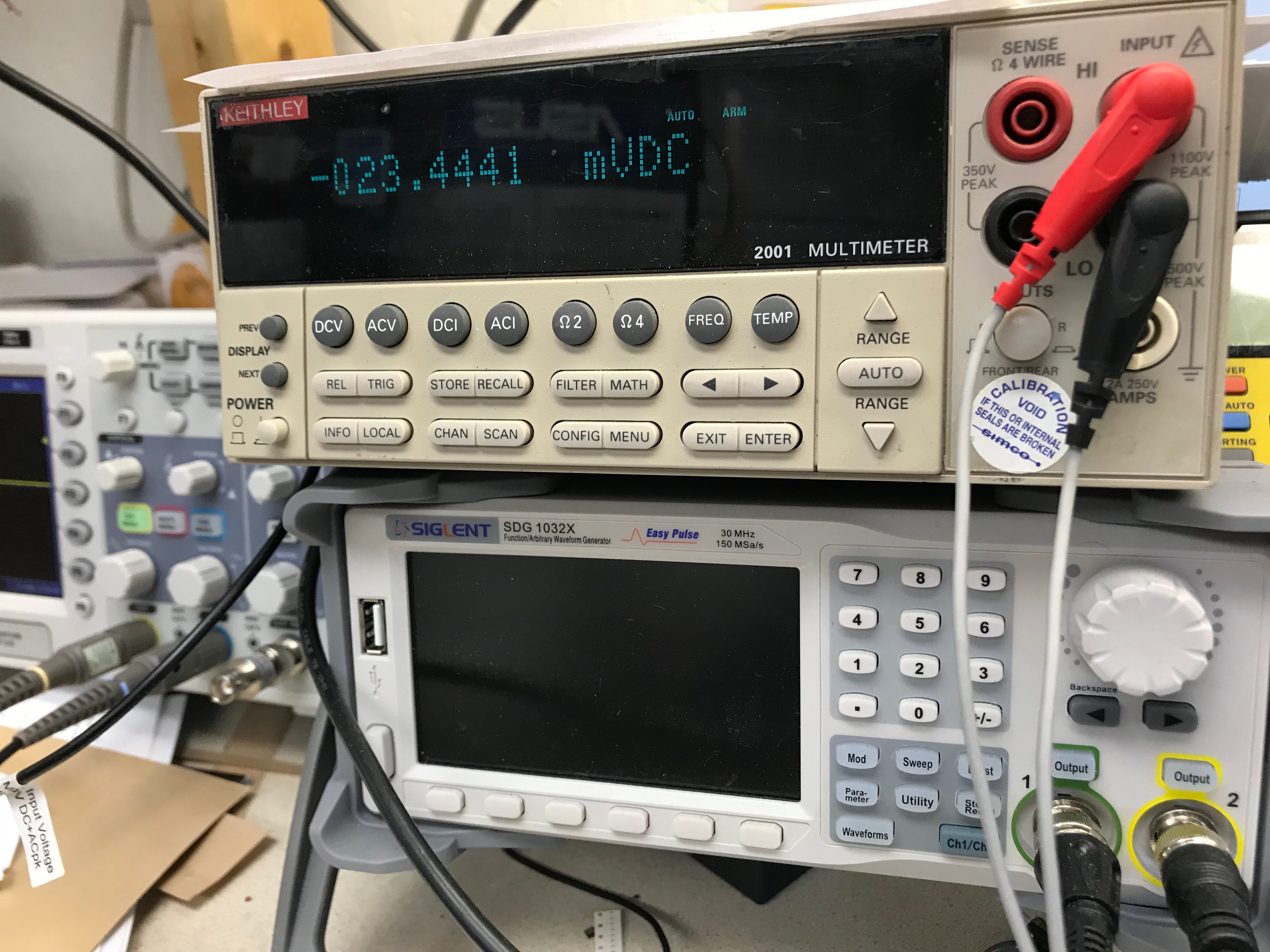

This is important. Battery not charging is a common fault. Sometimes it is a bad battery. Most of the time liquid damage has done its damage. The SMC must see proper battery present, battery charge control IC is a middle-man in this communication channel. If I find these signals at the battery – it proves all.

Check battery charge data line;

I like Pomona test leads, There is no such thing as a good CHEAP bench meter. It’s my livelihood – this Keithley 2001 is a good one for me. Doesn’t fall into battery saver auto-off in the middle of chasing down a problem…got enough on my mind at such a time…

Ahhh – the TPS51125 IC chip. It should give your macbook board the 3.3V and 5V it needs. The 3.3V is *so* important…This is what we need for the power button to work.

Late 2013 13″ Macbook Pro Retina Liquid damage

Sometimes a problem is hiding. Corrosion from liquid damage focused under the pad here. Things LOOK fine upon cursory overview…turns out; the via – to – chip leg continuity is lost. There was soon a fix and a happy customer.

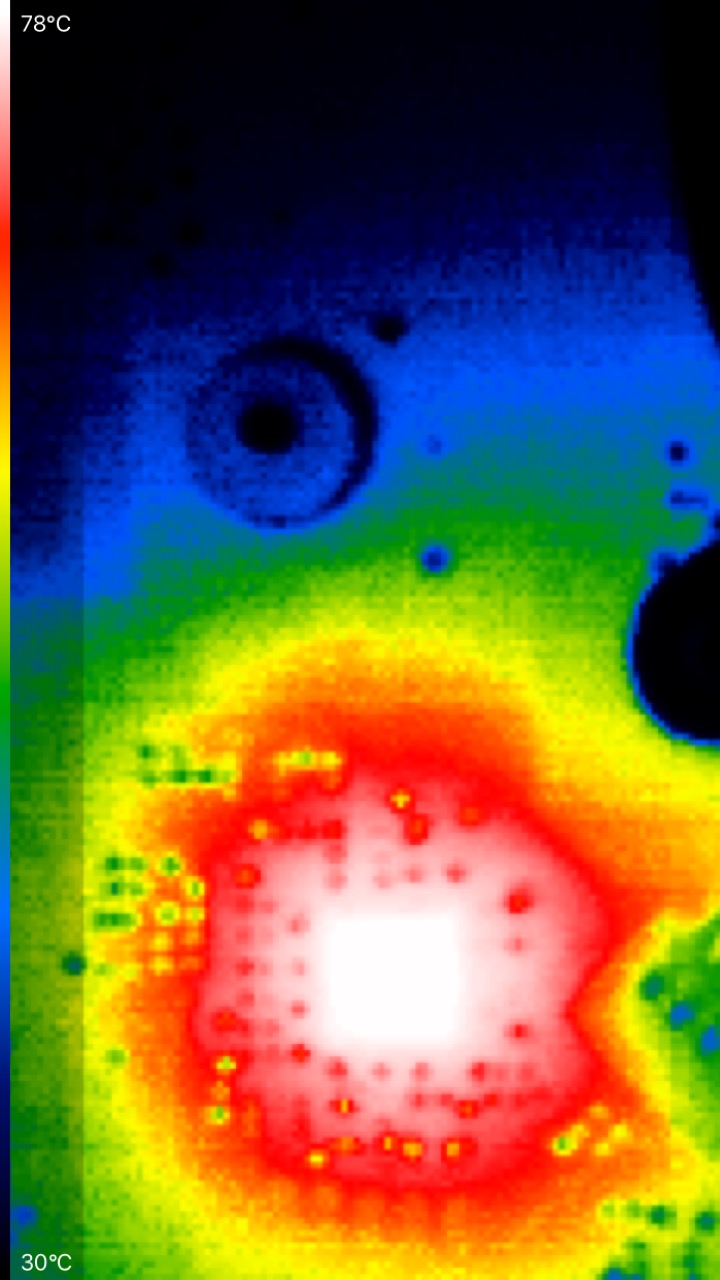

15” MacBook Pro Water Damage

Thermal image of water damaged macbook pro 15″ – IC that creates 5V and 3.3V power rails. See link – this one gets fixed, but GOOD!

Electronics Service & Repair

An LCD TV, a drone, a DSLR camera…whatever electronics gizmo causes you grief; call or email me, bring it in. If mending it is an economically viable option – we will dig in and do our geek best.